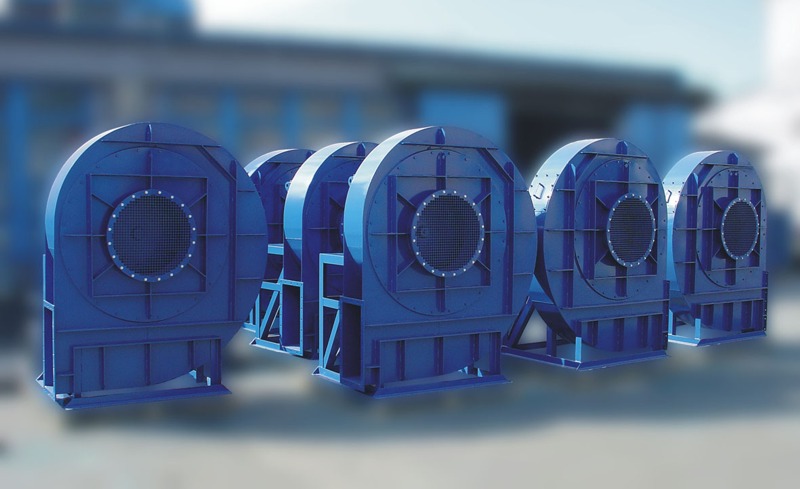

Fans

According to their performance, fans can be classified from lower to middle class, i.e. with air flow rate of up to 18 m3s-1 and total pressure of up to about 15,000 Pa or, a two-stage RVH 800 fan of up to 24 700 Pa. The sphere of application of these fans is very wide. From transporting clean compressed air through transport of slightly polluted air in industrial environments or transport of industrial waste in the wood processing industry, paper mills and similar operations, to special explosion-proof fans for ZONE 22 and ZONE 1 - formerly SNV 1, SNV 2, plastic coated or rubber coated fans supplied for ovens, boilers or for sucking off fumes in the chemical industry.

Production preparation, production and control process are carried out according to guidelines that have been set for granting the ISO 9001 certificate. The certificate audit was carried out by a British BSI REGISTERED FIRM and is periodically updated every year.

Overview of the parametres

Qv [m3hod-1]

|

Δpov [Pa]

|

| 540 – 64 800 |

600 – 15 000 |

RVI 315, RVI 400, RVI 500, RVI 630, RVI 800, RVI 1000, RVI 1250 |

| 2 000 – 13 000 |

720 – 11 500 |

RVJ 560, RVJ 630, RVJ 800 |

| 700 – 36 000 |

250 – 3 000 |

RSS 400, RSS 500, RSS 630, RSS 800, RSS 1000 |

| 200 – 42 200 |

250 – 2 400 |

OS 400, OS 500, OS 630, OS 800, OS 1000 |

| 2200 – 10 800 |

14 000 – 24 700 |

RVH 800 |

| 1000 – 64 500 |

580 - 880 |

AERO 315, AERO 400, AERO 500, AERO 630, AERO 800, AERO 1000 |

| 100 – 11 500 |

180 - 1020 |

RNS 200, RNS 250, RNS 315, RNS 400, RNS 500 |