Filter 40 RAV

Content

- Use of the filter equipment

- Basic technical details

- Main connection dimensions

1.USE OF THE FILTER EQUIPMENT

Filtration equipment is designed for extraction and filtration of dry metallic and non-metallic dust and small particles. They are suitable for suction of dust arising from the various technological processes. The ability to use filtering equipment must be consulted with the manufacturer. On this basis, appropriate filter membrane is chosen. The RAV filter 40 is designed to work in an environment without the danger of explosion when in normal temperatures of the surroundings ranging from -10 ° C to +40 ° C. Extractors are placed indoors or under shelter at least provide protection against the weather. If the dust is sucked, which can in certain circumstances be explosive must be installed outside the filter process line. Best in outdoor environment under a shed. The location of the investor decides on the basis of existing legislation. The filter 40 is equipped RAV with a system of regeneration by atmospheric air. This means that after a certain time the filter membrane will automatically under go re-blowing which leads to purification. If coarse particles are sucked into the filter it could lead, under certain circumstances, to poor regeneration of the filter membrane and the gradual clogging of the entire filter housing. The filter should therefore suck air mass devoid of coarse debris. As the first stage of filtration before this filter, a separator is designed to eliminate these particles.

Example of use: suction filtration and technological lines for the production of pellets from straw.

2. DESCRIPTION

Type of fans

|

RVI 400 5N explosion-proof

|

| Fan electric motor input |

3 kW |

Overall installed filter input

(without remov. transporter and tourniquet under the separator) |

max.7 kW |

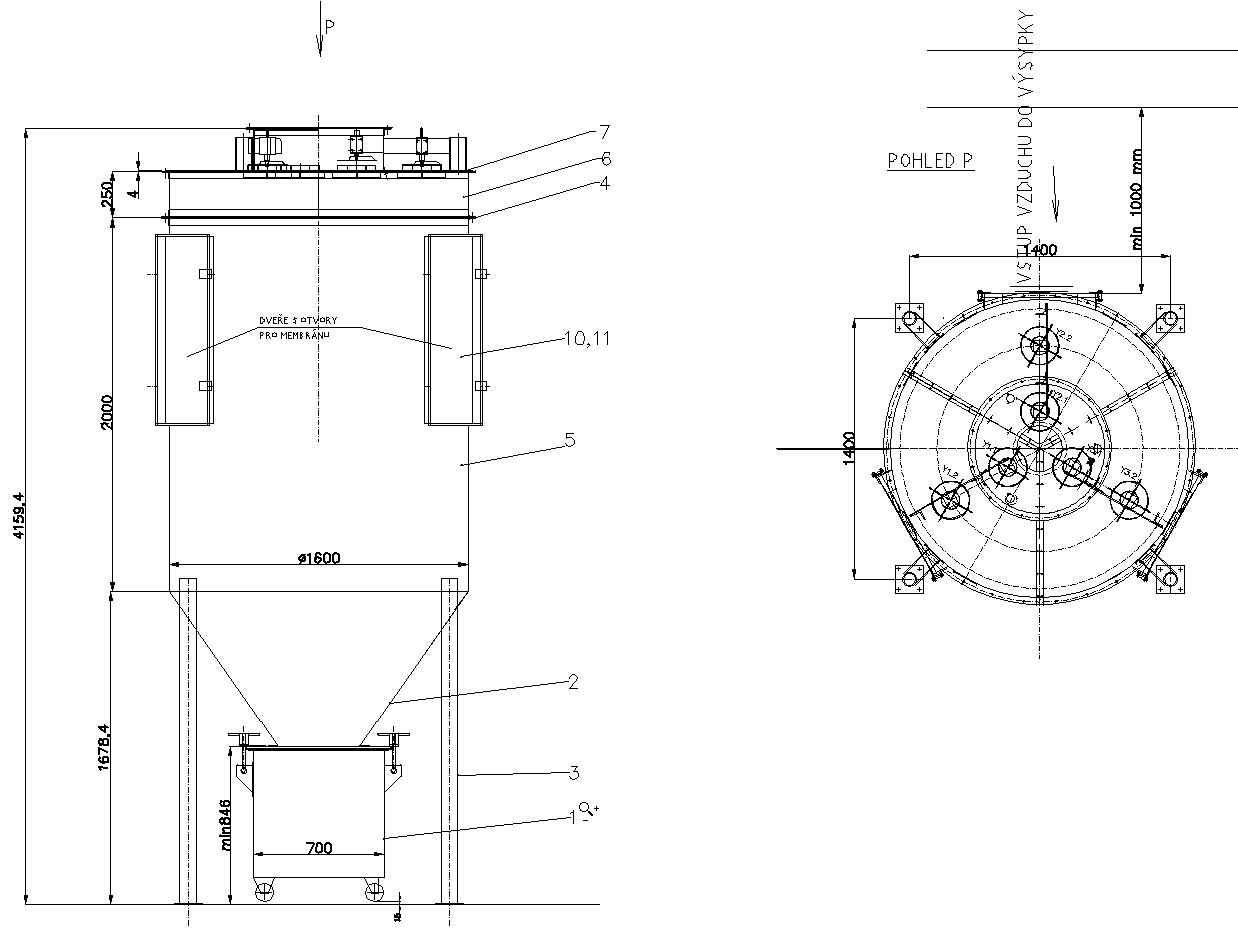

| Main dimensions width x depth x height |

3000x3200x4800 mm |

| Weight |

1420,- kg |

| Filtering surface |

39 m2 |

| Electromagnet EMSA 9517; 230V; AC; 490W; I nominal 2,2 A; I top 2,4 A |

6 ks |

| Type of tourniquet (rotational feed) |

NP 180 |

| Electromotor input under separator tourniquet |

0,25 kW |

| Number of filer hoses |

48 pcs |

Material designation for the type of filter material

- fleece

- underlying fabric |

BLUETEX CM 321393

POLYESTER SS

MATRIX |

| Separation efficiency of solid pollutants |

99,9 – 99,99 % |

| Final concentration of solids at the outlet |

max.10-20 mg/m3 |

Fan type may vary based on the segmentation process line.

3. MAIN CONNECTION DIMENSIONS