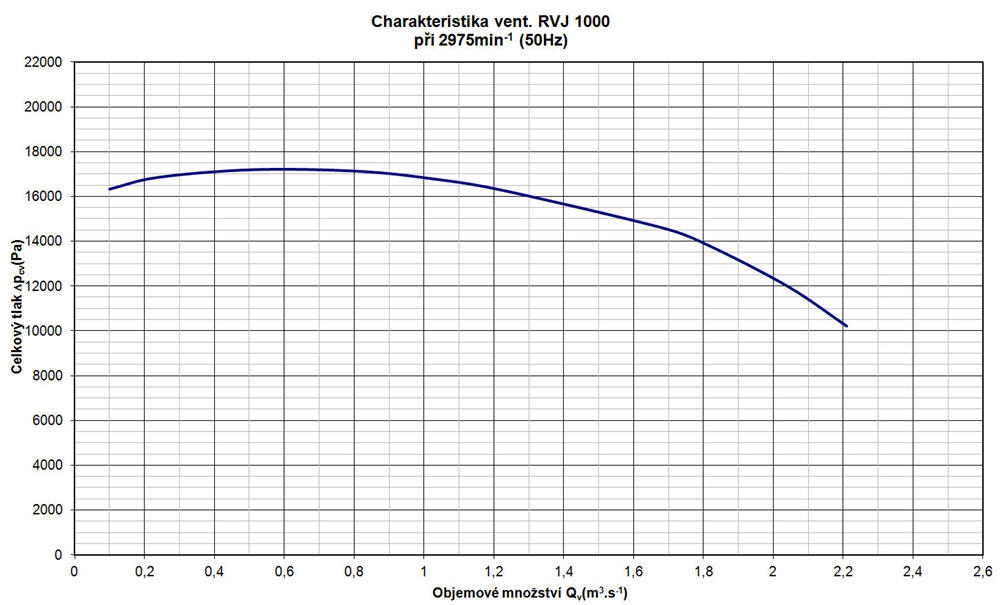

- Performance characteristics of the fan

ρ=1,2 kg/m3

- Description

RVJ single inlet suction fans according to PS 12 3344 are high pressure centrifugal fans, which are manufactured in sizes 560, 630 and 800. They are powered by electric motors, the impeller is mounted directly on the motor shaft or overhung on the shaft. To enhance power the fan of the size 560 and 630 use two wheel sizes and fans of size 800 use three orbital wheels. The fans do not have power regulation. Power can be regulated by an additional control device (see the catalogue of accessories). At a temperature above +70 ° C, the motor bearing disc mounted on the hub between the impeller and the volute casing motor is cooled by a refrigerant. The fans are made of sheet metal and profiles of steel class 11 (on request these can be of steel grade 17), ductile iron castings. The cooling discs are made of aluminium alloy. Volute (spiral) casing is welded and at the lowest point it is drained by pierced hole. The fan is stored together with an electric motor on a common frame. RVJ fan can be anchored on the concrete base or. Flexibly using isolators.

-

Use of the fans: the fans are used to transport clean or fine dust polluted air for industrial purposes. The fans cannot be used for the transport of air masses containing fibrous dust and air mass with additives that could cause clogging. Explosion-proof fans can be used to transport air mass and location in potentially explosive atmospheres. The fans are not gas-tight and should not be used for the transport of harmful and odorous air mass.

-

Working conditions: the fans can transport clean air without abrasive particles at temperature range of -20 ° C to +70 ° C. Fans with cooling disc up to a working temperature of +250 ° C. Fans are suitable for air mass transport and placement in an environment without the danger of explosion (BNV-CSN 332320) at an ambient temperature of -20 ° C to +40 ° C. Explosion-proof fans are certified for Zone 1. The fan can be operated only under conditions and parameters approved by the manufacturer according to the data plate on the fan.

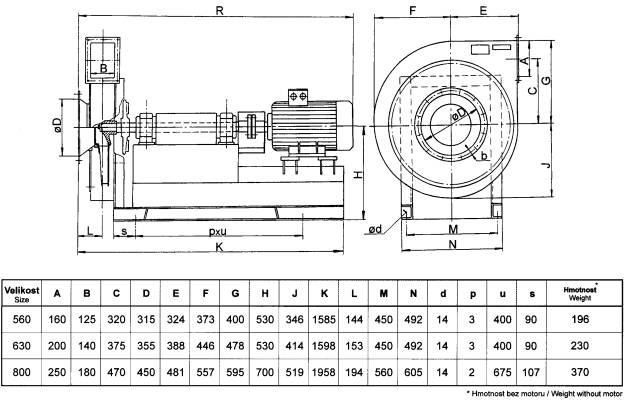

- Main connection dimensions

RVJ direct

| Size |

A |

B |

C |

D |

E |

F |

G |

H |

J |

K |

L |

M |

N |

P |

R |

d |

p |

u |

s |

Weight |

| 560 |

160 |

125 |

320 |

315 |

324 |

373 |

66 |

450 |

346 |

598 |

144 |

390 |

420 |

199 |

220 |

12 |

2 |

160 |

33 |

82 |

| 630 |

200 |

140 |

375 |

355 |

388 |

446 |

74 |

580 |

414 |

647 |

153 |

450 |

510 |

215 |

260 |

14 |

2 |

180 |

30 |

124 |

| 800 |

250 |

180 |

470 |

450 |

481 |

557 |

94 |

700 |

519 |

848 |

194 |

560 |

610 |

270 |

280 |

14 |

3 |

160 |

40 |

200 |

| 1000 |

180 |

180 |

610 |

280 |

809 |

710 |

712 |

830 |

688 |

1199 |

290 |

1000 |

1040 |

- |

- |

14 |

3 |

330 |

25 |

544 |

| 1250 |

200 |

162 |

695 |

320 |

921 |

810 |

810 |

930 |

786 |

1218 |

300 |

1200 |

1240 |

- |

- |

14 |

3 |

333 |

20 |

815 |

RVJ on coupling

Connecting dimensions of flanges

The positions of the spiral casing

The position of the volute (spiral) casing is determined when viewed from the side intake

The spring-mounted RVJ fans

| 560 |

100L |

3 |

P45 |

6 |

104,- |

|

539 |

390

|

101

|

199

|

220

|

-

|

-

|

126 |

| 112M |

4 |

112,- |

|

| 132S |

5,5 |

124,- |

|

| 132S |

7,5 |

132,- |

|

| 630 |

132S |

5,5 |

P46 |

6 |

165,- |

|

575 |

450 |

111

|

215

|

260

|

-

|

-

|

| 132S |

7,5 |

173,- |

|

| 160M |

11 |

193,- |

|

| 160M |

15 |

201,- |

|

| 160L |

18,5 |

211,- |

|

| 800 |

160M |

11 |

P47 |

6 |

269,- |

|

750 |

560 |

136 |

270 |

280 |

- |

- |

126 |

| 160M |

15 |

277,- |

|

| 160L |

18,5 |

287,- |

|

| 180M |

22 |

345,- |

|

| 200L |

30 |

P66 |

405,- |

|

750 |

430 |

146 |

| 200L |

37 |

425,- |

|

| 225M |

45 |

485,- |

|

| 250M |

55 |

575,- |

|

- Designation

An example of the directly driven RVJ fan, size 800 with number 3 impeller and volute (spiral) casing position:L 90° :

Fan RVJ 800 - 3 - L90° PP 12 3344.2 1LA0200LK02

| RVJ 800 |

type and size |

| 3 |

impeller number |

| L90° |

position of the spiral housing |

| PP 12 3344 |

norm number |

| .2 |

with cooling disc |

| 1LA0200LK02 |

electro-motor |

The fans are used to transport clean or fine dust polluted air for industrial purposes. The fans cannot be used for the transport of air masses containing fibrous dust and air mass with additives that could cause clogging. Explosion-proof fans can be used to transport air mass and location in potentially explosive atmospheres. The fans are not gas-tight and should not be used for the transport of harmful and odorous air mass. The fans can transport clean air without abrasive particles at temperature range of -20 ° C to +70 ° C. Fans with cooling disc up to a working temperature of +250 ° C. Fans are suitable for air mass transport and placement in an environment without the danger of explosion (BNV-CSN 332320) at an ambient temperature of -20 ° C to +40 ° C. Explosion-proof fans are certified for Zone 1. The fan can be operated only under conditions and parameters approved by the manufacturer according to the data plate on the fan.

. T. T.

T.